Why Glass Matters in Modern Food Packaging

Glass is one of the best materials for food packaging. It keeps food safe, fresh, and tasty, while offering high durability and sustainability, and supporting brand building. It's suitable for a wide range of industries, whether you're storing sauces, juices, baby food, or even beer glasses.

Glass is an ideal food packaging material because it is chemically stable, recyclable, and protects food from contamination, light, air, and moisture, ensuring long shelf life and product integrity.

1. Advantages of Glass for Food Packaging

Glass offers several distinct benefits when used in food packaging:

1.1 Safe & Non-Toxic

Unlike plastic, glass doesn’t leak chemicals into your food, even if it’s acidic (like pickles or tomato sauce). That means what you eat stays pure.

1.2 Keeps Food Fresh Longer

Glass blocks air, moisture, and light, which can spoil food. That’s why things like honey, olive oil, and wine last so long in glass bottles.

1.3 No Weird Tastes or Smells

Ever noticed how water in a plastic bottle sometimes tastes funny? Glass doesn’t absorb flavors or odors, so your food always tastes like it should.

1.4 Endlessly Recyclable

Glass can be melted down and reused forever without losing quality. Recycling it also uses less energy than making new glass, which is great for the environment.

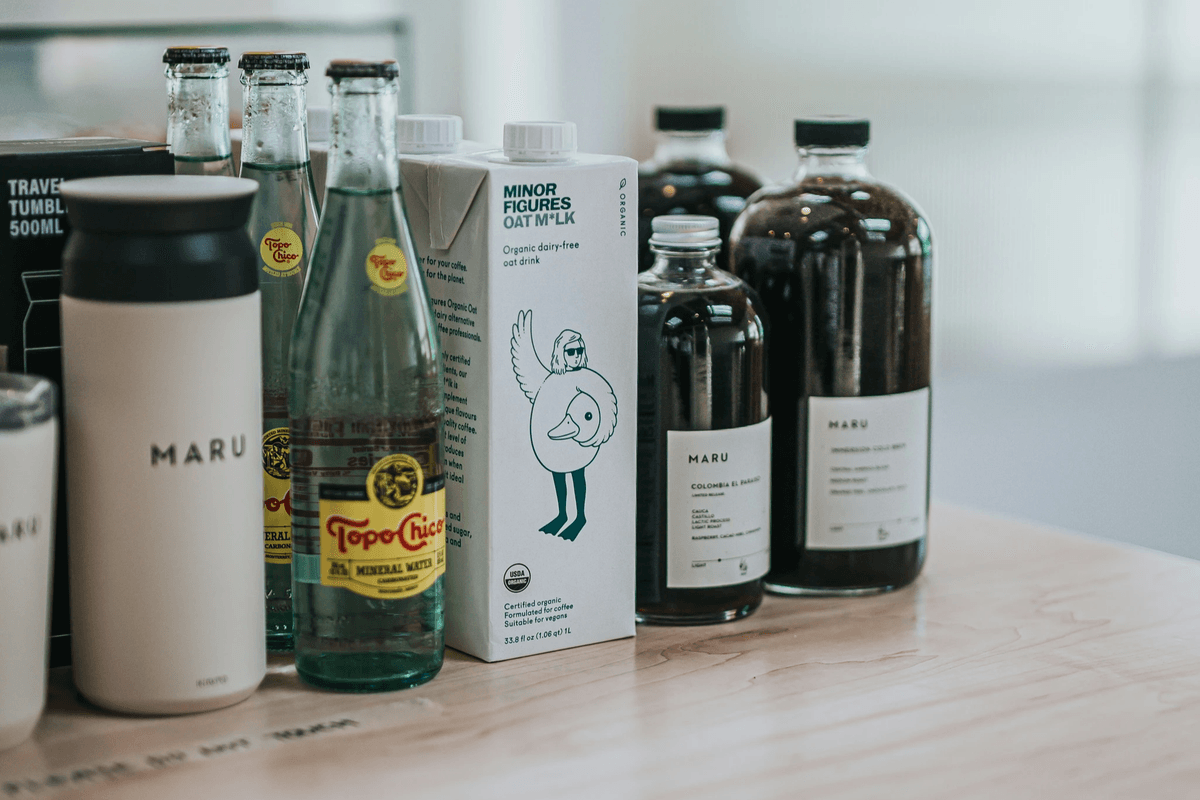

1.5 Premium Look and Consumer Appeal

Glass has a clear, glossy appearance that gives products a clean and high-end feel. Customers can see the product inside, which builds trust. Studies show that consumers often associate glass packaging with purity, safety, and quality

1.6 Heat Resistance and Reusability

Glass can withstand high temperatures, making it suitable for sterilization, pasteurization, and hot filling. It’s also ideal for refillable systems in sustainable packaging models like returnable jars or zero-waste retail

2. Disadvantages and Limitations of Glass Packaging

While glass is a top-tier packaging choice, it has some limitations to consider:

2.1 Fragility

Glass can break or shatter if dropped or mishandled, increasing the need for careful transport and robust secondary packaging. This adds to overall logistics complexity.

2.2 Higher Cost and Weight

Glass costs more to make and ship than plastic, which can add up for big brands.

2.3 Energy-Intensive Manufacturing

Producing new glass requires high-temperature furnaces, which consume significant energy. However, using recycled content (cullet) can reduce this impact substantially.

3. Typical Applications of Glass in the Food Industry

Glass is commonly used for foods that are acidic, aromatic, sensitive to light, or positioned as premium products. This includes:

- Baby food jars

- Pasta sauces and salsas

- Pickled vegetables and olives

- Honey and spreads

- Cooking oils and vinegars

- Alcoholic beverages (wine, beer, spirits)

- Dairy-based drinks and yogurts

Its versatility and product protection make it ideal for brands focusing on freshness, long shelf life, and premium appeal.

4. Regulatory Compliance for Glass Food Packaging

When packaging food products in glass, manufacturers must comply with international food safety regulations. These rules ensure that materials in contact with food are non-toxic, traceable, and safe for long-term storage.

4.1 Key Standards to Follow:

- European Union: Regulation (EC) No 1935/2004, ensuring all packaging materials are safe and inert when in contact with food.

- United States: FDA 21 CFR 175.300, covering coatings and surface treatments for glass containers.

- China: GB 4806.5-2016, national food-contact standard specific to glass containers.

4.2 Labeling and Documentation Requirements:

Food products exported in glass must include clear labeling, recycling symbols, and sometimes declarations of compliance or lab reports confirming safety (e.g., heavy metal migration test reports).

4.3 Reusable Glass Regulations:

In reusable packaging systems, especially in the EU, glass containers must meet hygiene and sterilization standards. These rules are becoming stricter under new sustainability frameworks like the Packaging and Packaging Waste Regulation.

Working with certified packaging suppliers and obtaining third-party testing (e.g., SGS, Intertek) is essential for regulatory compliance and international trade.

Glass might not be the cheapest option, but it’s one of the safest, most sustainable, and highest-quality choices for food packaging. If you care about keeping food fresh, avoiding chemicals, and looking premium, glass is worth the investment

5. Related Topics and Answers

Q1. What types of glass are used in food packaging?

Most food containers use soda-lime glass. Borosilicate glass is used when higher heat resistance is required.

Q2. Is colored glass better for food packaging?

Yes. Amber or green glass protects contents from light damage, making it ideal for oils or beer.

Q3. How do consumers view glass versus plastic?

Glass is perceived as safer, more natural, and environmentally friendly—especially in premium product categories.

Q4. Are there new developments in lightweight glass?

Yes. Manufacturers are developing thinner, stronger glass with protective coatings to reduce breakage and improve efficiency.

6. Summary

Glass is one of the most reliable, eco-friendly, and high-performance packaging materials for food products. It protects contents from air, moisture, and chemical contamination while preserving flavor and extending shelf life. With proper machinery and compliance practices, glass packaging supports both product quality and brand sustainability goals—making it a smart investment for the future of food.

Ready to upgrade your packaging to glass?

Contact us to explore our customizable filling, sealing, and labeling machines designed for glass containers. We help brands pack smarter, safer, and greener!