Why Packing Material Matters in Industry

In industrial production—especially for pharmaceuticals, cosmetics, and food—choosing the right packing material is critical. It's not just about protecting the product. It’s also about meeting safety standards, reducing costs, extending shelf life, and improving your brand image.

If you use the wrong material, your product could be damaged, spoiled, or even rejected due to non-compliance.

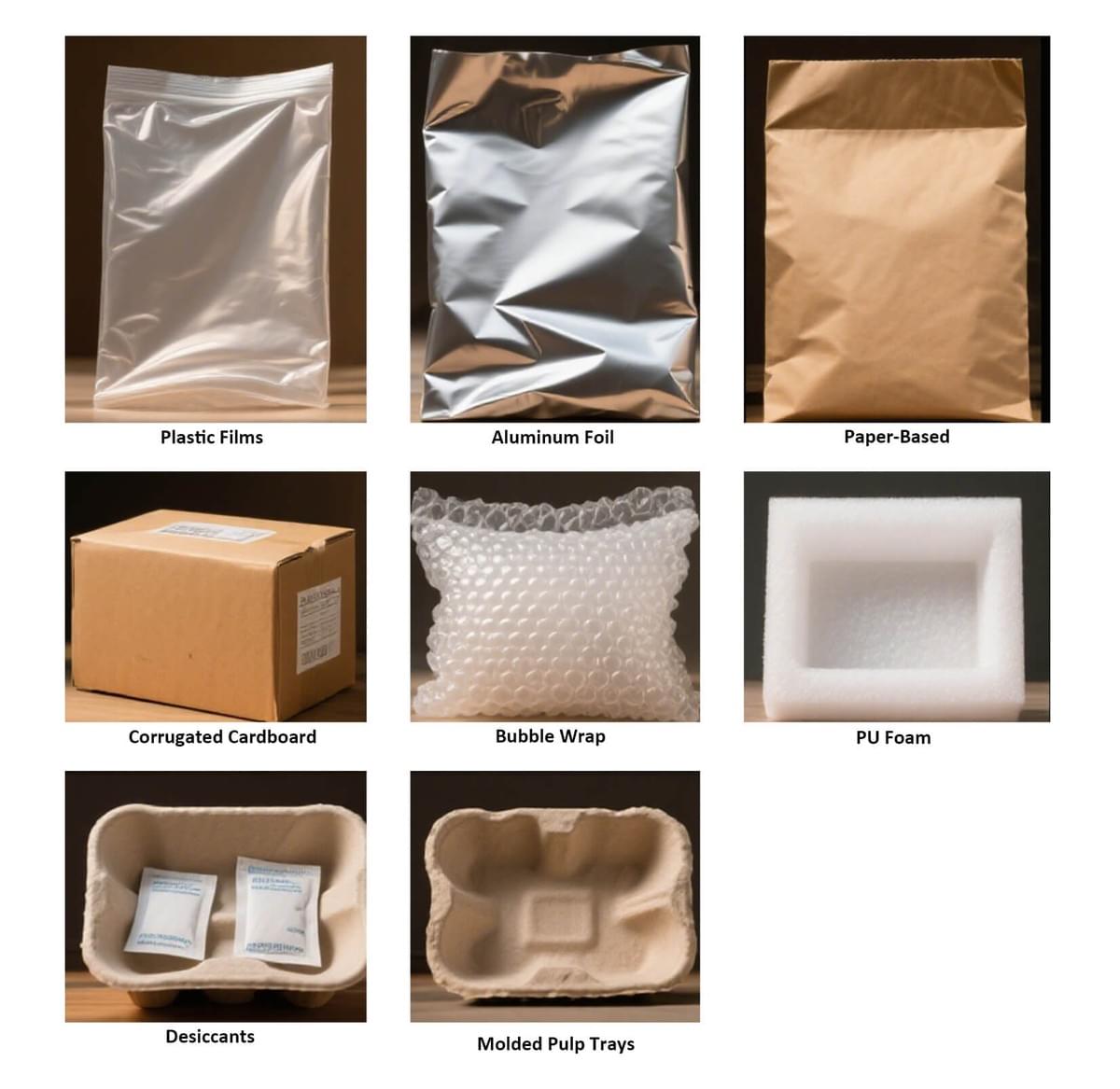

The most common packing materials in industry include plastic films, aluminum foil, paper, cardboard, foam, and moisture barriers like desiccants. The best choice depends on your product type, regulatory needs, and production method.

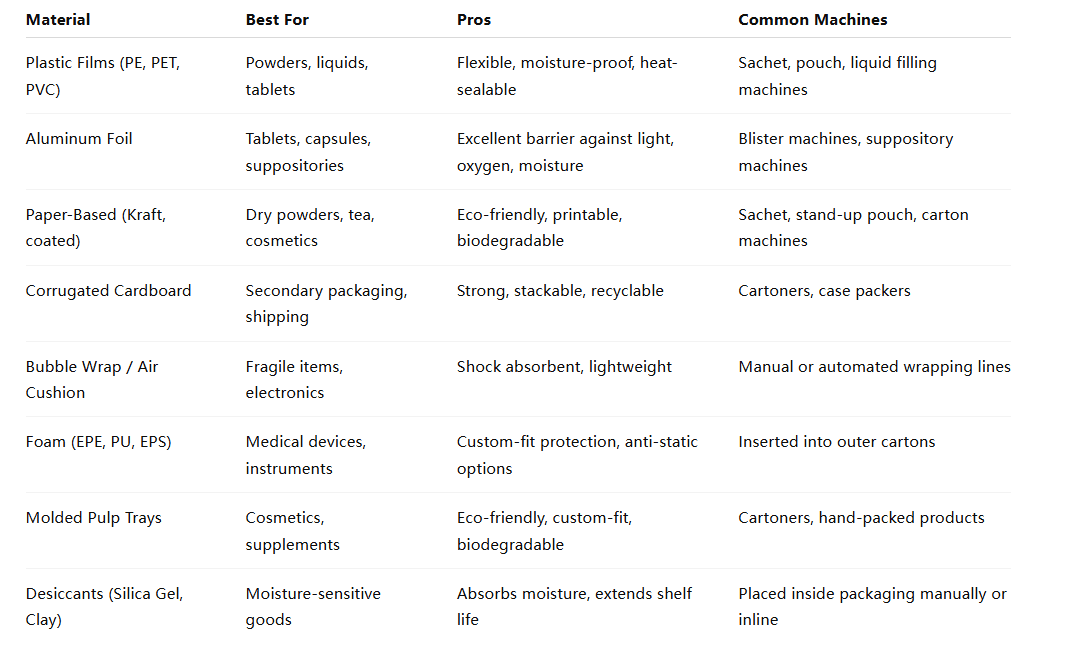

Common Types of Industrial Packing Materials

Here’s a comparison table showing the main packing materials used in industry and their applications:

How to Choose the Right Packing Material

When selecting your packing material, ask yourself these key questions:

1. What is the product type?

- Liquid → Use laminated films with barrier layers

- Solid tablets/capsules → Blister foil or paper pouches

- Fragile equipment → Foam, bubble wrap, cardboard inserts

2. Do you have to meet compliance standards?

- For pharmaceuticals, ensure materials are FDA, CE, or EU GMP compliant

- Use pharma-grade films or foils with proper certifications

3. Are sustainability goals important?

- Consider biodegradable films, recycled paper, or pulp trays

- Avoid excessive use of plastic if eco-regulations apply

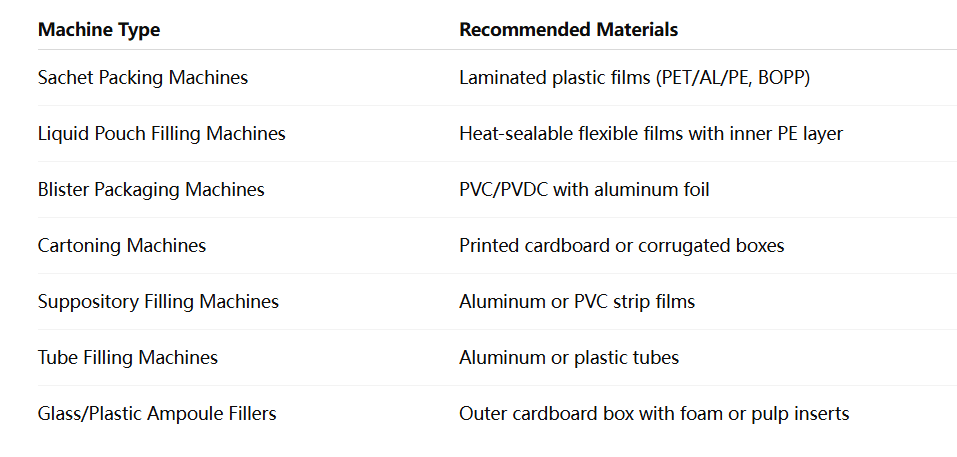

4. Which machine are you using?

Ensure your packing material matches the machine’s sealing, cutting, or forming capabilities

5. How will the product be transported or stored?

If exposed to heat, humidity, or shock, use high-barrier films and cushion packaging

Matching Packing Materials with Machine Types

Here's how materials align with packaging machines from LTPM CHINA:

Compliance and Sustainability Considerations

Many industries are moving toward eco-friendly and regulatory-compliant materials.

- Eco Options: Compostable films, recycled Kraft paper, molded fiber trays

- Pharma Compliance: Ensure materials meet USP Class VI, FDA 21 CFR, or EU food contact regulations

Tip: Always request a material safety data sheet (MSDS) and compliance certificate from your supplier.

The Role of Machinery in Material Compatibility

Even the best packing material won't work properly if it doesn't match your machine. LTPM CHINA’s machines are designed for flexibility and customization, allowing you to work with a wide range of materials and formats—especially in pharmaceutical and cosmetic industries.

Related Topics and Answers

1. What are GMP-compliant packaging materials?

Materials that meet Good Manufacturing Practice standards for safety, traceability, and hygiene. Includes food-grade films and blister foils.

2. How does packing material affect shelf life?

Barrier properties of materials (e.g., aluminum vs. PE) can significantly extend product shelf life by blocking moisture, oxygen, or UV light.

3. What packaging materials are recyclable or biodegradable?

Paper, cardboard, some bioplastics, and molded pulp trays are recyclable or compostable. Avoid mixed plastic/metal layers for recyclability.

4. Can I use the same film for powders and liquids?

Not always. Liquids require leak-proof laminated films, while powders can use simpler heat-sealable films.

5. Which packing machine is most flexible in material use?

Sachet and pouch packing machines are among the most flexible—they can run various laminated materials with minor adjustments.

Summary

- Industrial packing materials vary based on product type, regulations, and machine compatibility.

- Use plastic films, aluminum foil, paper, or foam depending on the specific needs of your application.

- Always consider compliance, sustainability, and machine limitations when making your choice.

Need help choosing the right packing material and matching machine?

Contact LTPM CHINA for expert advice and turnkey solutions tailored to your industrial needs.