During production, issues such as leaking bags, poor sealing, unsatisfactory appearance, or unstable batch quality are common sources of packaging complaints.

Many manufacturers first try to solve these issues by changing packaging materials or asking operators to “adjust the parameters,” but these fixes are often temporary.

In reality, most packaging problems are not caused by the materials themselves, but by the packaging machine system behind them. The machine connects the product, the packaging materials, and the final quality. If the system is poorly designed or poorly maintained, problems will continue to occur.In reality, most packaging problems are not caused by the materials themselves, but by the packaging machine system behind them. The machine connects the product, the packaging materials, and the final quality. If the system is poorly designed or poorly maintained, problems will continue to occur.

Packaging quality issues are often a direct reflection of insufficient machine precision, poor structural design, or inadequate coordination among modules.

Only by analyzing and improving the entire packaging machine system can stable and reliable packaging quality be achieved.

Sealing is the final and most crucial step of packaging. If sealing fails, even the highest-quality product and materials lose value.

Many sealing issues are related to the capability of the sealing system rather than simple parameter errors. Uneven heat distribution, unstable pressure, or worn sealing components can lead to weak or uneven seals.

For zipper bags, alignment accuracy is critical. If the machine cannot precisely position the zipper and the bag opening, the zipper will not close properly.

Solutions:

- Use a sealing system with precise control of temperature, pressure, and time, rather than relying on manual or rough adjustments.

- Regularly inspect and replace worn or uneven sealing molds.

- Choose machines equipped with accurate zipper alignment systems for zipper bags.

- Ensure sealing design matches the material thickness and structure.

2. Packaging Damage: Powder Leakage, Oil Leakage, Bag Breakage

Damage or leakage often occurs after filling or during bag handling. These issues are closely related to the filling system and the conveying system.

If the filling nozzle is poorly designed or incorrectly adjusted, the product may scrape the inner wall of the bag during filling. Sharp edges, excessive gripping force, or rough bag handling can also damage packaging materials.

For dense or high-fat products, the packaging machine must be specially designed to reduce impact and friction.

In many cases, the material is not “too fragile”—the machine’s impact force is simply too high.

Solutions:

- Optimize the shape and position of the filling nozzle to avoid contact with the bag wall.

- Use smooth, rounded grippers and control gripping force during bag handling.

- Reduce drop height and filling speed for viscous or oily products.

- Choose machines designed specifically for thick or laminated packaging films.

3. Poor Shelf-Life Performance: High Oxygen Levels, Fast Oxidation

When products oxidize too quickly or have a shorter-than-expected shelf life, the issue usually lies in the vacuum or nitrogen-flushing system.

Insufficient vacuum, low nitrogen purity, or inefficient gas replacement can leave excess oxygen inside the package.

Another common issue is timing: if sealing is not done immediately after flushing, air can flow back into the bag.

Gas-related issues are usually system coordination problems—not just gas supply problems.

Solutions:

- Improve vacuum efficiency and nitrogen purity to ensure effective oxygen removal.

- Optimize the gas-flushing structure for higher replacement efficiency, rather than simply increasing gas volume.

- Seal immediately after flushing to prevent air re-entry.

- Ensure packaging speed matches gas replacement capability.

4. Appearance Issues: Wrinkles, Contamination, Print Misalignment

Packaging appearance directly affects brand perception. Wrinkling, seal contamination, or print misalignment often result from improper film handling.

Incorrect film tension leads to misshaped bags and printing deviation.

If the sealing area is not clean, oil or product residue can contaminate the seal and affect both appearance and seal strength.

High-quality packaging is the result of precise machine control—not operator skill alone.

Solutions:

- Use machines with stable and adjustable film tension control systems.

- Ensure the photo-eye tracking system is accurate and properly calibrated.

- Clean sealing molds regularly to prevent oil and powder buildup.

- Improve filling accuracy to minimize product contamination in the sealing area.

5. Batch Inconsistency: Unstable Quality, Hard-to-Reproduce Results

Some production lines run well one day and poorly the next—even with the same materials and products. This is a typical sign of equipment aging and lack of calibration.

Worn mechanical parts, drifting sensors, and outdated control systems can cause subtle parameter changes that accumulate into serious quality issues.

Without preventive maintenance and standard calibration, consistent packaging quality cannot be guaranteed.

Unstable machine condition always results in unstable packaging quality.

Solutions:

- Implement a regular Preventive Maintenance (PM) plan.

- Periodically calibrate sensors, sealing systems, and weighing systems.

- Replace aging components before they affect product quality.

- Standardize machine parameters instead of relying on operator experience.

From the issues above, it’s clear that packaging problems rarely exist independently—they are the result of machine precision, structural design, system coordination, and maintenance practices working together.

To truly reduce packaging failures, manufacturers must shift from fixing individual problems to improving the entire packaging system.

Related Topics & Answers

- Why do the same packaging materials behave differently on different machines?

Because machines vary in precision, structure, and control. Material performance depends on how the machine manages heat, pressure, speed, and positioning. - Which machine features are often overlooked during model selection?

Film tension control, sealing stability, and long-term component durability—despite their critical role in packaging quality. - What special requirements do high-density or oily products have?

Smoother filling, gentler handling, stronger sealing systems, and better contamination control. - What role does preventive maintenance play in packaging quality?

It keeps machine performance stable, prevents parameter drift, and reduces unexpected quality failures. - How can you determine whether a problem is machine-related or process-related?

If the issue recurs across different shifts or operators, it is usually caused by the equipment or system—not the process settings.

Summary

Packaging problems are the final result—not the starting point.

Sealing, filling, gas flushing, film handling, and machine stability are all interlinked.

Only by treating the packaging machine as a complete system—and applying the right technical solutions—can manufacturers achieve stable, high-quality packaging.

If your goal is to reduce packaging failures and improve long-term production stability, choosing the right packaging machine system is essential. Work with a manufacturer who can provide customized solutions, full-line evaluation, and long-term technical support.

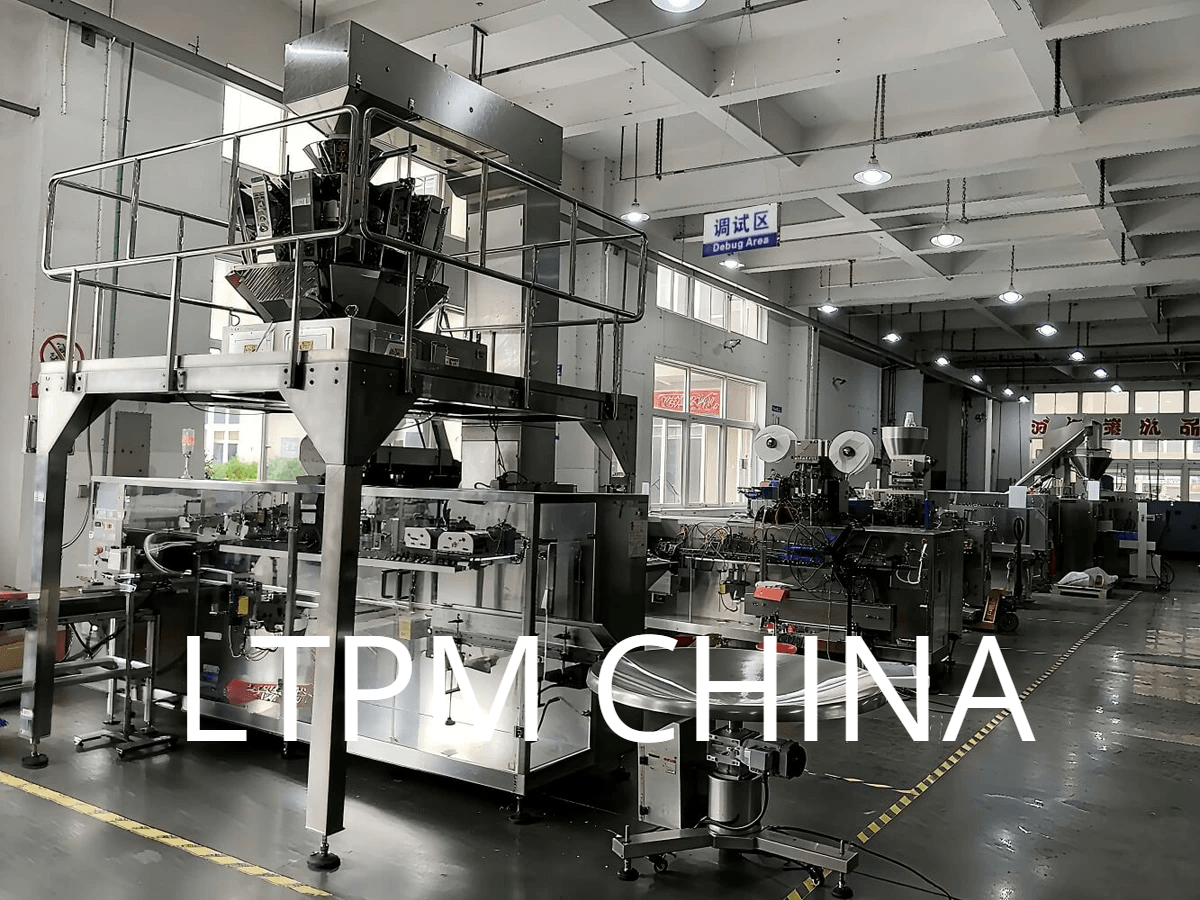

LTPM CHINA offers a five-year warranty, over 20 years of manufacturing experience, and customers in more than 30 countries. If you’d like to learn more about packaging machinery, feel free to contact us—we look forward to working with you.