According to the latest global market research data, almond butter has become the nut butter segment with the highest compound annual growth rate, far exceeding that of traditional peanut butter. This is a clear signal that the entire food industry is shifting towards a "value-driven" approach . This is prompting almond butter manufacturers to re-evaluate their product formulations and production technologies.

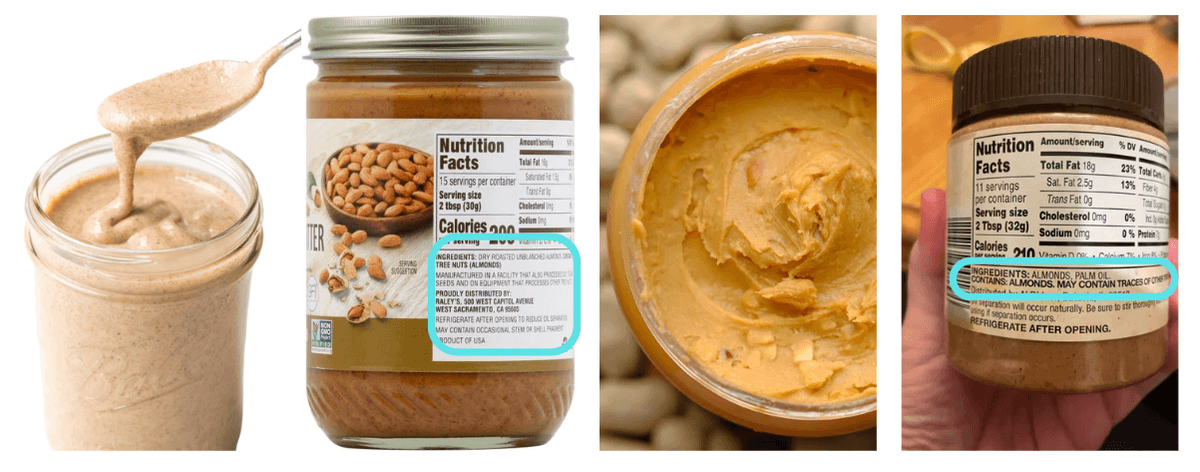

Consumers are increasingly favoring the concept of "clean label." Products with fewer ingredients are often perceived as healthier, more authentic, and more premium. Brands that emphasize "no additives, no stabilizers" often achieve better positioning, even at a higher price.

The market demands a clean ingredient list for almond paste , but almond paste is naturally unstable and requires food additives to maintain its stability. This has become a major bottleneck hindering the industry's move into higher-end markets.

Common additives in almond paste and their functions

1. Preventing oil and sauce separation: emulsifiers and stabilizers

Problem:

Almond paste is a mixture of solid and liquid phases. After standing, the oil naturally floats up and the solid particles sink, resulting in the separation of the oil and paste .

Common additives: hydrogenated vegetable oil, palm oil, soy lecithin .

Working principle:

- Hydrogenated vegetable oil/palm oil can increase the thickness of the sauce and physically prevent the oil phase from separating.

- Soy lecithin is an emulsifier with a molecular structure that is hydrophilic on one end and lipophilic on the other. It can form a thin film at the interface between oil and solids, reducing surface tension and allowing them to coexist. It mainly improves uniformity and ductility .

2. Preventing Oxidative Rancidity: Antioxidants

Problem:

The unsaturated fatty acids in almonds oxidize when exposed to oxygen, creating a rancid taste. This not only affects the flavor but can also generate harmful substances.

Commonly used additives: natural vitamin E (tocopherol), TBHQ (tert-butylhydroquinone), BHT (butylated hydroxytoluene), BHA (butylated hydroxyanisole) .

Working principle:

These antioxidants can react with oxygen preferentially or interrupt the oxidation chain reaction . By "sacrificing themselves", they protect the oil in almond butter from oxidation and effectively extend the shelf life.

3. Adjust flavor and taste

Issue:

Pure almond butter may taste too monotonous or slightly bitter; the texture may need to be adjusted to suit different consumer preferences.

Commonly used additives:

- Sweeteners (such as sugar, syrup): provide sweetness, balance the taste, and mask any off-flavors.

- Salt: highlights the aroma of nuts and enhances the overall flavor.

- Food flavoring: Enhance or unify the nutty flavor of the product.

4. Maintaining texture and preventing caking

Problem:

Sauces can become hard or lumpy during storage due to temperature changes or improper moisture content.

Commonly used additives: anti-caking agents (such as silica) .

Working principle: Anti-caking agent has a strong adsorption capacity and can absorb excess water and oil . It can maintain the fluidity of the powder or granules of the sauce and prevent it from sticking together.

Chemical additives can solve almond paste problems more quickly and conveniently. However, when their use runs counter to market trends, the only solution is to go upstream and solve the problem through innovative production processes. This means that the core competitiveness of production will shift from "recipe design" to "process design."

Breakthrough - Packaging technology replaces chemical additives

1. Solving the problem of oil and sauce separation: precision homogenization and mechanical stabilization technology

Oil-sauce separation

is a natural physical phenomenon, but its impact can be minimized through precise mechanical intervention, thereby reducing or even eliminating dependence on emulsifiers and stabilizers.

Optimized grinding process: Utilizing low-temperature, slow grinding technology. Traditional high-speed grinding generates high temperatures, exacerbating oil precipitation and instability. Low-temperature, slow grinding better preserves the almond cell structure, resulting in gentler oil release and a more evenly distributed paste.

Equipment: Stone mill or ultra-fine grinder with precise temperature control system.

Equipment combination:

- A buffer tank with scraper agitation: This is core equipment . In the temporary storage tank before filling, the sauce must be continuously stirred by a slow-speed agitator and a scraper that adheres closely to the tank wall. The scraper prevents the sauce from adhering to the tank wall, while the agitator ensures uniform distribution of the sauce throughout the tank, completely eliminating sedimentation.

- In-line static mixer: A series of fixed spiral elements installed inside the conveying pipe. As the paste flows through, it is continuously divided, merged and recombined, achieving continuous homogenization, ensuring that the paste reaching the filling head is of the same quality as that in the buffer tank.

Strategy: Even with optimal processing, almond butter, which is completely additive-free, may still exhibit a slight degree of oil-salt separation. Manufacturers should proactively address this by stating on the label, "This is a natural phenomenon. Please stir before consumption," thus transforming this characteristic into a credible indicator of the product's purity and additive-free nature.

2. Solving Oxidative Rancidity: Integrated Nitrogen Protection System

The most thorough way to combat oxidation is not to delay it, but to eliminate the reaction condition—oxygen. Nitrogen filling technology is a physical method to achieve this goal.

Internal deoxygenation of the sauce: dynamic degassing and nitrogen injection. Before entering the filling line, the sauce passes through a vacuum degassing tank . Under negative pressure, dissolved microbubbles (primarily oxygen) within the sauce are extracted and extracted. Subsequently, high-purity (over 99.5%) nitrogen is immediately injected into the sauce. This directly reduces the initial oxygen content of the sauce to extremely low levels. This "internal" approach to the problem is far more effective than traditional methods that only treat the air at the bottle head , but it also incurs higher costs .

Technology: long needle nitrogen displacement filling ; packaging headspace oxygen displacement .

- Protection during filling: The filling valve adopts a light-shielding design, and while the sauce is being filled, a nitrogen curtain is formed around the sauce to reduce its contact with the air during the falling process.

- Post-filling protection: After filling, a slender nitrogen-filling needle penetrates the bottom of the container and fills it with nitrogen. Since nitrogen is less dense than air, it "expels" the remaining air (rich in oxygen) from the bottom up through the bottle mouth, and then the bottle is immediately capped.

3. Integrated Solution: Building a "No Additives" Production Chain

A true upgrade is not the accumulation of single point technologies, but the integration of them into a seamless closed-loop system:

Raw almonds → Cryogenic grinding → Entering the buffer tank with scraper wall stirring → Passing through the dynamic degassing and nitrogen filling unit → Transported by the static mixer → Filling under nitrogen protection → Long needle replaces the headspace air → Instant capping

Summarize

In our experience working with almond paste manufacturers, we’ve witnessed this shift firsthand: many clients are moving away from emulsifiers or preservatives and focusing instead on how to design their production lines to replace some of the functionality once provided by additives.

Almond paste powder is also very popular. Almond paste powder is made from traditional almond paste (which contains all the almond components, especially the oil ). Through processes such as spray drying , it is transformed into a powder that dissolves quickly in water or milk. The goal is to reconstitute the paste into an emulsion with a texture close to that of the original almond paste .

Almond butter, whether or not it contains additives , has its own advantages and disadvantages. If you're considering transitioning to an additive-free almond butter, feel free to contact us and we'll design a customized solution for your specific situation. We have extensive experience with both almond butter and almond butter powder. With the right process design, clean label and product stability are no longer issues.