Why Sealing Matters More Than You Think

It’s easy to see sealing as just the final step of packaging — but in reality, it’s one of the most crucial.

A poor seal can lead to leakage, product spoilage, or contamination, while a strong, consistent seal ensures freshness and product safety.

Using an automated stand-up pouch packing machine allows you to achieve high-quality, repeatable seals efficiently and reliably.

Key Factors to Consider Before Sealing

A perfect seal starts with understanding your product, material, and packaging goals.

- Powders (e.g., milk powder, pharmaceutical granules): Fine particles may contaminate the sealing area and prevent bonding. Some machines solve this by air-cleaning the sealing zone before sealing.

- Oily products (e.g., nuts, snacks, creams): Oils can affect adhesion. In such cases, materials with high anti-contamination properties, such as RCPP, are preferred.

- Liquids and viscous products: Require seals that can withstand internal pressure. For acidic or alkaline formulations (like vitamin concentrates or chemical gels), the inner film must be chemically resistant to prevent corrosion over time.

Your processing method also affects sealing:

- Vacuum packaging requires a strong seal to resist pressure changes.

- Nitrogen flushing demands excellent airtightness to prevent gas leakage.

- Sterilization or pasteurization requires seals that withstand high heat without delamination or cracking.

For brands that prioritize a smooth, clean seal appearance, precise temperature and cooling control are essential to avoid wrinkles and ensure consistent presentation.

How Modern Sealing Systems Work

A high-quality stand-up pouch packing machine does far more than simply “press and seal.” It’s an intelligent system designed to automatically balance temperature, pressure, and time for different materials and product types.

- Temperature Control System: The heart of the process. Modern sealing jaws are equipped with precision thermocouples to maintain even heating (typically within ±2–3°C), preventing under- or over-sealing.

- Adjustable Pressure System: Pressure must match the material type and pouch thickness. Low pressure can cause weak seals; too much pressure can thin or melt the edges.

- Dwell Time: The period the jaws remain closed during sealing. It determines how deeply heat penetrates the film. Thicker materials require longer dwell times.

- Efficient Cooling System: Immediately after sealing, cooling jaws compress the seal area to solidify it, enhancing strength and visual smoothness.

- Anti-Contamination Features: Air jets, cleaning blades, or sponges remove powder or oil residues before sealing. Machines can also include vacuum or nitrogen modules to remove air or inject inert gas before sealing, further extending product shelf life.

With over 20 years of experience, LTPM CHINA provides advanced stand-up pouch packaging machines with multiple configuration options to ensure strong, airtight seals.

If you’re facing sealing issues or want to upgrade your production line, our experts are ready to help.

The Science Behind a Quality Seal

Stand-up pouches are more complex than they appear. They consist of multiple layers of materials, each serving a specific purpose.The outer layer provides strength and printability, the middle layer blocks light and oxygen, and the inner layer melts to form the seal.

The inner sealing layer is usually made of polyethylene (PE) or polypropylene (PP). Depending on the material type (LDPE, LLDPE, CPP, or RCPP), the sealing temperature typically ranges between 130°C and 200°C.

If your material includes foil or nylon, heat will take longer to penetrate, meaning sealing time and pressure must be adjusted accordingly.

Effective sealing requires a balance of temperature, pressure, and dwell time. These three factors must work together to create a strong, smooth, and airtight seal.

Common Seal Types:

- Fin Seal: Film-to-film seal, common in form-fill-seal machines.

- Side Seal: Reinforces the gusseted bottom for added stability.

- Top/Zipper Seal: Provides reusability and enhanced product protection.

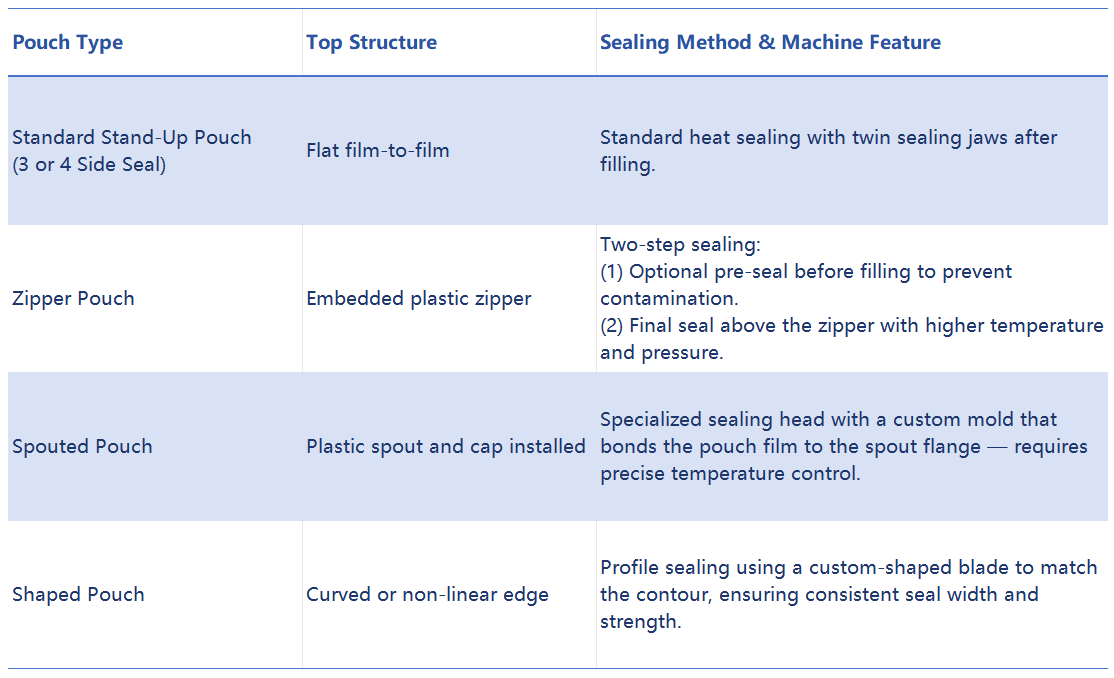

Different Seal Methods for Different Pouch Designs

Not all stand-up pouches are sealed the same way. The sealing method depends on the pouch structure and intended use.

Each type requires specific machine configurations, sealing molds, and parameter settings. Choosing the right equipment ensures strong, reliable, and visually clean seals every time.

Modern Sealing Technologies and Industry Trends

Technology continues to advance rapidly in pouch sealing.

- Ultrasonic sealing uses mechanical vibration instead of direct heat, making it ideal for temperature-sensitive or powder-contaminated products. According to the Journal of Food Engineering, it can also save up to 40% in energy consumption.

- Induction sealing uses electromagnetic fields to generate heat within a foil layer, creating tamper-evident seals.

- Laser-assisted sealing offers extreme precision in temperature control for high-end applications.

Today’s machines feature smart sensors and real-time temperature feedback systems, allowing operators to monitor every seal cycle and ensure consistent quality.

Choosing the Right Equipment for Your Needs

When selecting a pouch sealing system, consider more than just machine size or speed. Think about your product type, film structure, required output, and regulatory standards.

For pharmaceutical and cosmetic production, machines must comply with GMP, CE, and FDA standards to ensure hygiene, safety, and traceability.

LTPM CHINA offers a full range of customizable filling and sealing systems, backed by a five-year warranty, precise temperature and pressure control, and optional vacuum or gas-flushing modules. It’s the ideal choice for export-grade production lines requiring reliability and compliance.

Conclusion

A well-sealed stand-up pouch may seem like a small detail, but it defines the entire product experience.

A proper seal not only protects the contents but also builds consumer trust, reinforces product quality, and strengthens brand reputation.

By understanding your packaging materials, product characteristics, and sealing requirements — and using modern automated equipment — you can achieve durable, attractive, and airtight seals that meet international standards every time.

Ready to enhance your sealing quality and production efficiency?

Explore LTPM CHINA’s customized stand-up pouch packaging machines, designed for precision, durability, and full GMP compliance.