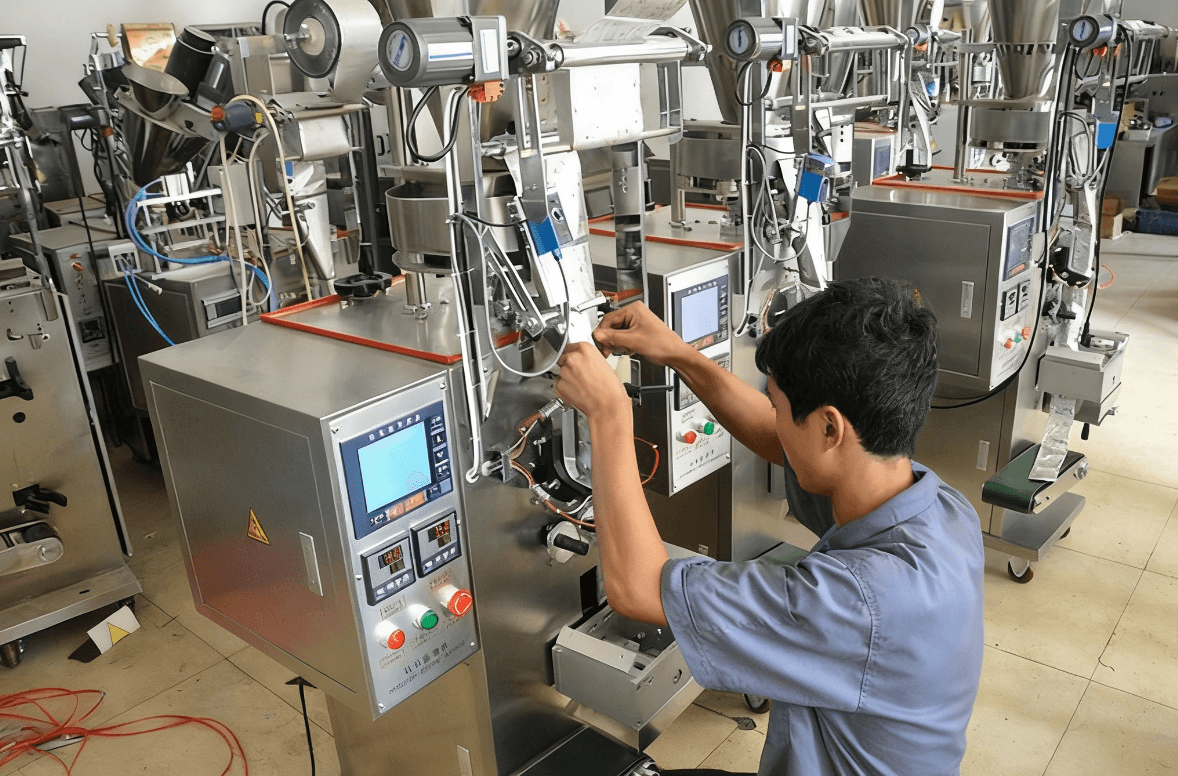

Sachet packing machines have become the backbone of many modern production lines, widely used in the pharmaceutical, food, and cosmetics industries. These machines ensure precise filling, reliable sealing, and compliance with hygiene packaging standards. However, to maintain consistent performance, regular maintenance is essential.

Maintaining a sachet packing machine involves establishing a routine cleaning program, ensuring correct sealing temperature and alignment, regularly lubricating moving parts, and systematically checking the condition of sensors. Neglecting these steps can lead to product leakage, film misalignment, and unexpected downtime.

Core Principles of Sachet Packing Machine Maintenance

To ensure long-term, stable operation, always follow these five key principles:

- Cleanliness: Regularly remove product residues to prevent blockages or contamination.

- Accuracy: Keep sealing and filling systems precisely calibrated to minimize material waste.

- Lubrication Management: Apply the proper lubricant or grease at scheduled intervals to reduce friction and prevent wear.

- Regular Inspection: Pay attention to unusual sounds, abnormal vibrations, or temperature changes.

- Safe Operation: Always disconnect power and release residual air pressure before performing maintenance work.

Step-by-Step Maintenance Guide

1. Cleaning and Hygiene

Cleaning is the first and most important step. After each production run:

- Wipe the sealing jaws, filling nozzles, and film path with a soft cloth.

- Use non-corrosive cleaning agents suitable for your product type (such as food-grade or pharmaceutical-grade cleaners).

- Remove all residues, as buildup can block heat transfer and cause weak or uneven sealing.

Tip: Never use sharp tools to scrape residues — they can damage sealing surfaces. Instead, use a soft brush with an alcohol-based cleaner.

2. Lubricating Key Components

The moving parts of the machine — such as the gearbox, chains, bearings, and pneumatic joints — require regular lubrication.

If you hear unusual noises or notice rough movement, it may indicate insufficient lubrication. Lack of lubrication increases friction, causing vibration or motor overheating.

Solution: Apply lubricant to moving joints and chains. Avoid over-lubrication, as excess oil can attract dust and impurities.

3. Monitoring Temperature and Seal Quality

The sealing jaw temperature typically ranges from 130°C to 180°C, depending on the film type.

- If the temperature is too low, the film will not seal properly and may leak.

- If it’s too high, the film can scorch or wrinkle.

Inspection Method:

- Use a digital or infrared thermometer to confirm the actual sealing temperature.

- If the temperature fluctuates by more than ±5°C, recalibrate the controller or replace the temperature sensor.

4. Sensor Check and Film Alignment

Photoelectric sensors read the film’s marks to determine where each sachet should be cut.

If the film is dirty or misaligned, sachets may be too long, too short, or misprinted.

Solution:

- Clean the sensor lens with a dry cloth.

- Check if the film’s printed marks are correctly positioned.

- If cutting errors persist, readjust the sensor alignment settings.

5. Pneumatic and Electrical System Maintenance

Most sachet packing machines rely on compressed air to move parts and seal sachets.

If the air pressure is unstable, sealing quality may deteriorate. Loose electrical wiring can also cause random shutdowns or temperature irregularities.

Solution:

- Inspect air hoses for cracks and replace any damaged ones.

- Tighten electrical connectors and use dry air to remove dust.

- If the machine suddenly stops, check the air supply and electrical connections before restarting.

Common Faults and Solutions

FaultPossible CauseSolutionAbnormal noiseLoose parts or lack of lubricationStop immediately, lubricate moving parts, and tighten connectorsPoor sealing qualityIncorrect temperature or contaminated sealing jawsClean the sealing area and readjust the temperatureFilm slippageInsufficient film tension or worn rollersAdjust film tension or replace worn rollersInconsistent filling volumeBlocked nozzle or poor material flowClean and inspect the filling systemInaccurate cuttingBlunt blade or misaligned cutterReplace the blade and realign the cutting unit

Consequences of Neglecting Maintenance

Failing to maintain your sachet packing machine can result in:

- Reduced packaging quality: Sachet leakage or incomplete sealing.

- Frequent production interruptions: Increased unplanned downtime and reduced efficiency.

- Higher repair costs: Minor issues can escalate into major repairs.

- Shortened equipment lifespan: Continuous friction and heat damage key components.

- Increased hygiene risks: Residual powder or liquid can contaminate new product batches.

Just a few minutes of preventive maintenance each day can save hours or even days of production downtime.

Recognizing Warning Signs

Your sachet packing machine will often give early signs of trouble:

- Vibration or shaking: Indicates loose or misaligned parts.

- Uneven sachet length: Sensors need cleaning or recalibration.

- Temperature alarms: Faulty sensors or controllers may need recalibration.

- Slower filling speed: May be caused by abnormal material moisture or incorrect auger speed.

Extending Machine Lifespan Through Proper Maintenance

By following these care steps, you can:

- Maintain sealing precision within ±0.5 mm.

- Reduce film waste by 10–15%.

- Extend the service life of critical components by several years.

- Ensure stable output and consistent product quality.

Summary

Maintaining a sachet packing machine is not complicated. The key is to keep it clean, watch for unusual noises or movements, and respond quickly to signs of wear or misalignment. Proper maintenance not only ensures product quality but also keeps your machine efficient, safe, and reliable for years to come.

If you’re looking for a durable, easy-to-maintain, and high-quality sachet packing machine, contact us today.

Our expert team provides customized sachet packaging solutions, comprehensive maintenance support, and a five-year warranty — ensuring your production line runs smoothly and efficiently.