What is a stick-pack?

Stick packs are long, thin, tube-shaped, single-serve packaging . They are widely used in the pharmaceutical, nutraceutical, food, and beverage industries. Whether it's powdered supplements, instant coffee, liquid medications, or energy gels, stick packs offer excellent control over portion size and cost-effective packaging . This article details the stick pack production process, the machines used, and why this packaging format has become one of the most popular packaging choices worldwide.

Stick packaging production process

The production of stick packs is a highly automated continuous process that starts with the film roll, goes through forming, filling, sealing, slitting and finally becomes an individual pack.

1. Film unwinding and transport

At the start of production, a large roll of composite film (often composed of multiple layers, such as PET/aluminum foil/PE) is automatically unwound and smoothly fed into the production line . The machine's tension control system ensures that the film is neither too tight nor too loose during transport, preventing deformation or breakage .

2. Printing and encoding ( optional )

If the packaging requires labeling with the brand name, production date, batch number, or instructions for use, this can be done before the film is formed. The film can be printed using a digital printer or laser coding system. High-precision sensors within the machine ensure the precise placement of each mark .

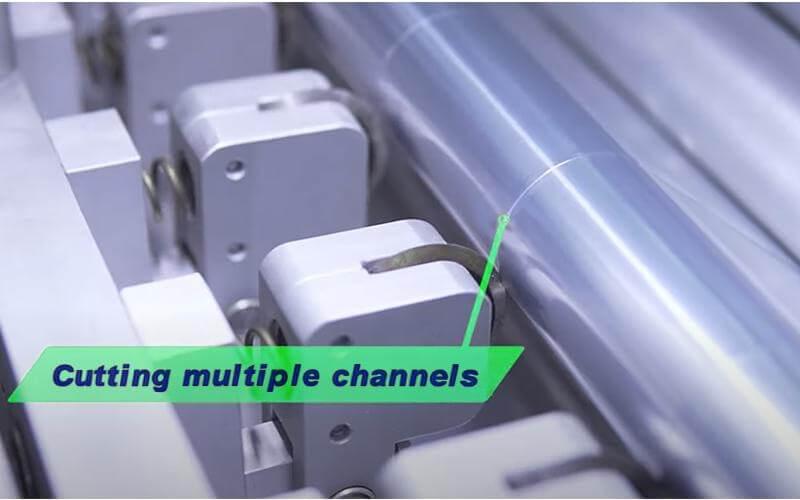

3. Cutting multiple channels

Wide film is slit into multiple narrow strips based on the number of machine lanes , significantly improving efficiency. For example, a ten-lane machine can produce ten packages simultaneously . Each narrow strip enters a different lane and is processed in parallel.

4. Forming into a tube

Each film strip passes through a former (usually a conical or rectangular guide tube) and is gradually rolled into a thin tube. After the edges overlap, a vertical heat sealer completes the longitudinal seal to form a closed tubular structure.

5. Accurately fill the contents

The filling method varies depending on the product type:

- Powders (e.g. protein powder, coffee): Use an auger or dosing cup to ensure consistent portion size per packet.

- Liquids (such as oral solutions, honey): Use piston pumps or peristaltic pumps for precise distribution using micro-control technology.

This process requires attention to hygiene and precision, especially in the pharmaceutical and food industries.

6. Sealing and slitting

After filling, the tubular package is drawn to a horizontal sealing mechanism . Heat-sealing blades seal the top and bottom of the package, forming individual units. High-speed packaging machines are often equipped with multiple sets of sealing jaws to simultaneously seal multiple packages. Slitting involves a rotary blade or shearing device that separates the continuous package into individual strips.

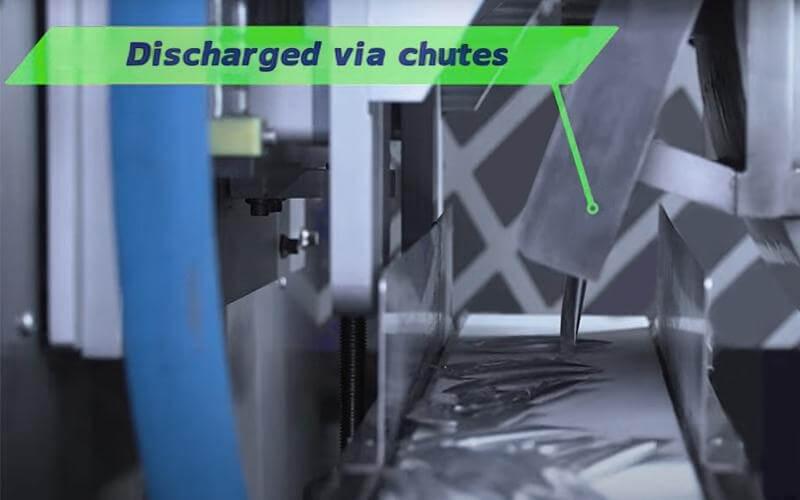

7. Discharging and secondary packaging

Finished products are discharged via chutes or conveyors or enter the next stage for secondary packaging, such as automatic cartoning machines, wrapping machines, or case packers. During the discharge and secondary packaging process, equipment such as checkweighers and metal detectors are often used to eliminate defective products in real time to ensure quality.

8. Quality Inspection and Compliance Control

In the pharmaceutical industry, each batch is also subject to seal strength testing, microbial limit testing , etc. to ensure that the product complies with GMP (Good Manufacturing Practice) or FDA regulations.

Strip packaging machinery type

Single-lane machines :

compact and ideal for small batches, research labs or products requiring tight process control.

Multi-lane machines : designed for high-volume production, capable of producing hundreds of packs per minute.

For pharmaceuticals, stick packaging lines are often integrated with additional equipment such as checkweighers, metal detectors, and cartoning systems to meet GMP standards.

Stick packaging films and materials

Strip packaging films are usually multi-layer composite materials. Common structures include:

- Outer layer (printing and protective layer) : PET (polyester film), BOPP (biaxially oriented polypropylene), or nylon are commonly used. These materials are abrasion-resistant and stretch-resistant , and their surfaces are suitable for high-quality printing, making them ideal for the outer layer of composite films. For example, PET's higher hardness facilitates package shaping, while nylon offers greater toughness and puncture resistance, making it commonly used for hard or grainy contents.

- Middle layer (high-barrier layer) : Aluminum foil is commonly used (VMPET aluminized film is also gaining popularity) . It effectively blocks oxygen, water vapor, and UV rays, preventing products from moisture, oxidation, and deterioration . It effectively protects photosensitive ingredients (such as vitamins and probiotics) and hygroscopic products (such as instant drinks and powders).

- Inner layer (heat-sealing layer and safety layer) : Commonly made of polyethylene (PE) or polypropylene (PP) . Ensures heat-sealing performance and safe contact with the product.

With the increasing awareness of environmental protection, biodegradable materials (such as PLA) and recyclable structures are gradually being promoted, reducing environmental impact while ensuring functionality.

Why choose stick packaging? The core advantages at a glance

- Precise dosage: Each package contains a fixed dose to avoid waste or errors during use.

- Efficient and material-saving: Strip packaging is produced using a continuous tube-making process. Compared to pre-made bags with three- or four-side seals, this reduces the waste of butt joints and scrap, increasing material utilization by up to 40%. This reduced material usage not only reduces packaging costs but also alleviates environmental pressure, aligning with the trend toward green packaging.

- Portable experience: Lightweight and compact, suitable for putting in pockets and bags, and use anytime, anywhere.

- Extend shelf life: High barrier material effectively prevents moisture and oxidation, keeping the product fresh.

- Brand display: Good printing adaptability helps highlight brand image and product information.

Related questions and answers

1. What is the difference between stick packs and sachets?

Sachets are typically wide, flat, and sealed on three or four sides, while stick packs are narrower, tubular, and sealed vertically and horizontally. Stick packs require less material and are easier for consumers to open and pour. However, sachets offer a larger capacity and are generally more suitable for products such as granules and pastes that require more space.

2. Can the stick packing machine be used for both powders and liquids?

Yes , but this requires changing the filling module. For example, a standard model may have an auger filler for powders, but switching to a piston pump allows it to handle liquids. Some high-end models offer this option at the touch of a button. Stick packers are designed to handle a wide variety of product types. An auger filler is used for powders like instant coffee or pharmaceutical powders, while a piston or peristaltic pump is used for liquids like syrups, gels, or liquid dietary supplements.

3. Which industries benefit most from stick packs?

- Pharmaceuticals: such as cold granules and oral liquids;

- Health food: protein powder, vitamins;

- Food and beverages: coffee, sugar, condiments;

- Daily chemical products: shampoo, skin care product sample packs.

4. How fast can the stick pack machine produce?

Production speed depends on the number of lanes. A single-lane machine can produce 30-60 packs per minute, while a multi-lane system with 10 lanes can produce hundreds of packs per minute. The specific choice depends on the scale of production and needs.

5. What factors should buyers consider when choosing a stick packaging machine?

Key factors include:

- Product type (powder, liquid, granules).

- Product form (powder/liquid/granules).

- production capacity requirements.

- Film material and barrier requirements.

- Whether it needs to comply with pharmaceutical or food-grade specifications.

Subsequent scalability, such as whether to connect to a cartoning machine, weighing machine, etc.

Summary

Stickpack production is a highly automated, efficient, and versatile process for converting film rolls into convenient single-serve packaging. From food and beverages to pharmaceuticals and cosmetics, stickpacks offer a practical and sustainable way to deliver products to consumers. Understanding the production process, materials, and machine options can help businesses choose the solution that best meets their needs.

If you're looking for a pharmaceutical-grade stickpack machine or a complete turnkey stickpack production line, we offer custom solutions backed by a five-year warranty. Contact us today for a free consultation, sample testing, or a special first-time purchase discount.